Rahul Beniwal, with over 15 years of experience under his belt- in software development, cloud infrastructure, product management, and systems architecture. These experiences have helped...

The world is evolving with advanced technologies emerging every now and then. One of the mind-blowing innovations that is set to extend the boundaries of innovation is Digital Twin Technology. It refers to a virtual representation of a physical object or entity or process.

There are three elements of digital twin technology:

- A real-world entity

- The software form of the real-world entity as a digital twin

- The data that connects the two elements.

These three elements form the core of digital twinning. Visual representation is not a prerequisite for digital twinning but most of the digital twins have 2D or 3D computer-aided design (CAD). Digital representation or model can also look like a database, a set of equations, or a spreadsheet.

Though data connection is important it is not necessarily a way to process. This is what differentiates it from other similar concepts like the Internet of Things and other AI-enabled innovations. The link at times is only from the physical entity to the digital twin counterpart and not vice versa.

Types of Digital Twins

Digital Twins can be categorized into four types:

- Component Twins or Part Twins: As the name suggests, it is associated with parts and components like mechanical subassemblies.

- Asset Twins or Product Twins: This refers to interaction in Digital Twins between one or two components.

- System Twins or Unit Twins: As the name suggests, in this type of digital twin, the assessts assemble and form a complete functioning unit.

- Process Twins: Now that we have a complete system, it is time for process twins. As the name clearly says it is associated with processing and working together of the different parts for the ultimate goal.

There are various different ways to categorize digital twin technology. One of the other categorizations divides it into infrastructure twins and network twins. Where the first one is associated with the physical parts while the latter is associated with the process and operation.

Benefits of Digital Twinning

Digital Twin technology leverages various next-generation innovations like the Internet of Things and artificial intelligence etc, to bring efficiency and cost-cutting in various industries. And here I am highlighting some of the key benefits:

- Enhanced operational efficiency by having more timely data and faster, more effective production.

- More effective and less expensive R&D and reduced time to market because of physical prototypes.

- Which can be expensive and hard to modify, are replaced with virtual prototypes, which are more flexible and produce more data.

- Better product quality as digital twins help identify defects earlier in the production process.

- Longer equipment uptime from predictive maintenance enabled by analyzing individual digital twins instead of having to shut down all the equipment to isolate a problem.

- More accurate and efficient remote monitoring of facilities and equipment through integration with their digital twins.

- Improved product end-of-life processes, such as refurbishment and recycling, thanks to more accurate information about the age and contents of a product.

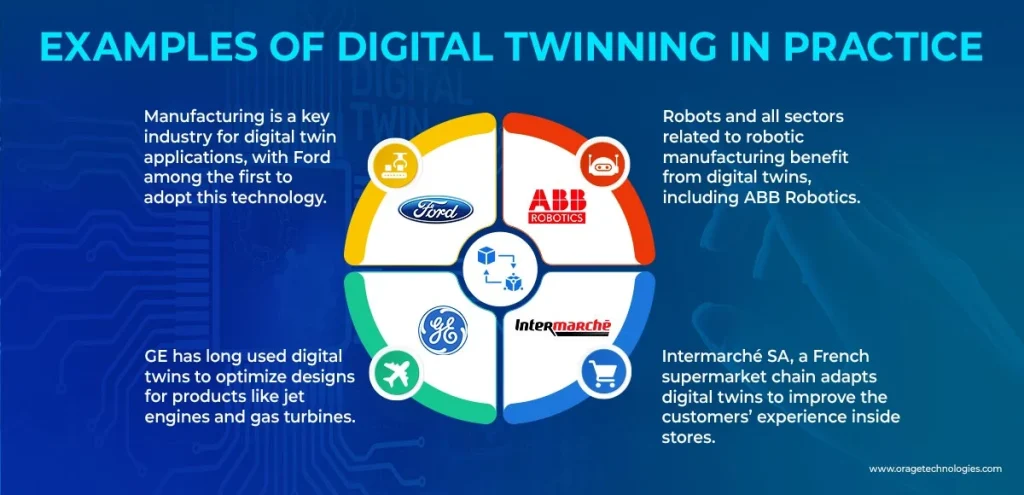

Examples of Digital Twinning in Practice

By 2040 the innovation in Digital Twinning is going to grow to $125.9 Billion from $6.5 Billion. This advanced technology has revolutionized many fields and here are some examples of how companies are leveraging digital twins technology today.

Ford – Manufacturing

Manufacturing is among the most important industries and definitely one of the areas most capable of using digital twins. Ford was one of the first companies to adopt this technology; it is for this reason that through the use of a digital twin, the company is able to monitor and even control the manufacturing processes in real time. This will allow maximum efficiency in production and resource usage because they are working with a common goal.

In another area, Ford manufacturing has also used digital twins to improve the product design line. For example, the use of technology has been done to model the various production methods with regard to the product strength.

GE – Aviation

Digital twins have long been used in GE as a tool for optimizing the design of diverse products, including jet engines and gas turbines. This way, the company is able to build a “virtual engine” that could let it try various concepts and approaches in a safely controlled environment before attempting to implement them in actual business scenarios. This cuts the odds of failure and increases the speed at which a product gets to the market.

The real-time monitoring features of digital twins have delivered substantial value to GE’s customers; $1.6 billion in value up to 75% savings in product waste and up to 30% savings on costs; due to the holistic view provided by digital twins across the product lifecycle.

ABB – Robotics

Robots and all sectors related to robotic manufacturing benefit from digital twins, including ABB Robotics. ABB has used it to simulate robotic configurations on such simulated production lines before assembling the actual line. This approach eases configuration does not require prototyping, and reduces time to market.

Digital twins let ABB model every aspect of robot implementation which results in a faster setup as well as better incorporation to factories and production lines necessary for meeting today’s consumption rates.

Intermarché – Retail

Intermarché SA, a French supermarket chain adapts digital twins to improve the customers’ experience inside stores. This way, customer movements and interaction with the products are followed which reveals valuable information about customers. They are mostly applied to enhance the placements of products, develop better designs, and design effective marketing strategies.

In addition to the customer analysis, Intermarché has successfully used the concept of digital twins in the supply chain. For instance, through technology, users learn how weather conditions influence inventory and determine the amount of products they should stock.

The Living Heart Project – Healthcare

Picture a population where one could walk through the human heart through a digital twin model. The Living Heart Project is one of the unique kinds of interventions that involve using virtual models of the heart to change the system of teaching and learning in the healthcare industry. Physical hearts could never replicate how researchers can study the dynamics of heart-shaped structures.

Such an approach can facilitate an increase in the knowledge of many types of heart diseases, enhancement of treatment strategies, and augmentation of patient protection. Since heart disease remains the leading cause of death globally, this technology affords the capability to decrease the cost, bring down delayed outcomes, and improve results.

Shanghai, China – Urban Planning

Shanghai’s population has and still is growing at a very fast rate, with over 28.5 million people. It turns to digital twins to enhance this. This endeavour, Beijing-based 51World supports this effort by developing 3D models and a range of simulations of the city at a micro level.

Such virtual city replicas are particularly useful in that they allow planners an opportunity to try out new concepts and ideas without the risk of having to spend extra money replacing failed experiments As well as providing a valuable tool for efficient resource distribution. Digital twins also track the city’s current performance, therefore means that planners can still intervene and make changes whenever necessary to guarantee sustainable development.

The Bottom Line:

Digital Twin technology is a future technology that is sure to be beneficial for every industry and company. It can reduce the cost and increase the efficiency of every process by replicating the virtual replica of the physical object.

Also Read: The Future of Cloud “Edge Computing: What it is and How it Works?

Rahul Beniwal, with over 15 years of experience under his belt- in software development, cloud infrastructure, product management, and systems architecture. These experiences have helped him design scalable solutions and businesses. He’s lived the highs and lows of entrepreneurship, guided teams through growth and change, and stayed curious about how technology continues to shape the way we work and live. In his writing, he blends deep technical insight with real-world business know-how, offering readers tools and perspectives that come from actual experience.

More Posts