Divya Stuti, with over 5 years of experience in Digital Marketing & Content Writing, has a knack for turning complex Marketing strategies, trends, and jargon...

Do you know how Fortune 500 companies saved $427 billion (luminisindia.com), Motorola achieved 99.99966% defect-free quality (qualitymag.com), and General Electric saved $12 billion in 5 years (isixsigma.com)? Behind all these successes, Six Sigma was the main ingredient.

Today, the buzz around this concept has driven the business stakeholders towards learning and adopting it. From reducing errors by 99.9% to increasing customer satisfaction and saving billions, the power of Six Sigma can not be overstated.

But six sigma is not any other course that you can do in a few weeks or days and adopt it like a pro. It requires skill, understanding, time, and above all, right guidance.

Though good courses are expensive and tough to get into, we have got you a free guide to master Six Sigma. We start with baby steps, stating the foundational concepts, and will take you to mastering it with black belt six sigma mastery.

Let’s get started with understanding what it actually is.

The Basics: What is Six Sigma?

The term “Sigma” is a Greek alphabet that denotes standard deviation. A “Six Sigma” process is one where the variation is so small that the nearest specification limit is six standard deviations away from the mean.

It is a methodology driven by data that focuses on improving the performance of different processes, products, and services. By identifying and eliminating the errors, defects, and inefficiencies, they make things better, faster, more reliable, and scalable for the company as well as the customers.

Its definition can come in three different ways:

- Many people consider it a philosophy that promotes a proactive approach towards perfection.

- Most companies use it as a performance metric to find defects and inefficiencies and move towards improving the services and expanding their revenue streams.

- The most accepted way of defining it is by understanding it as a methodology. In this definition, it uses a standard process known as DMAIC to identify and fix the matters that truly affect any business.

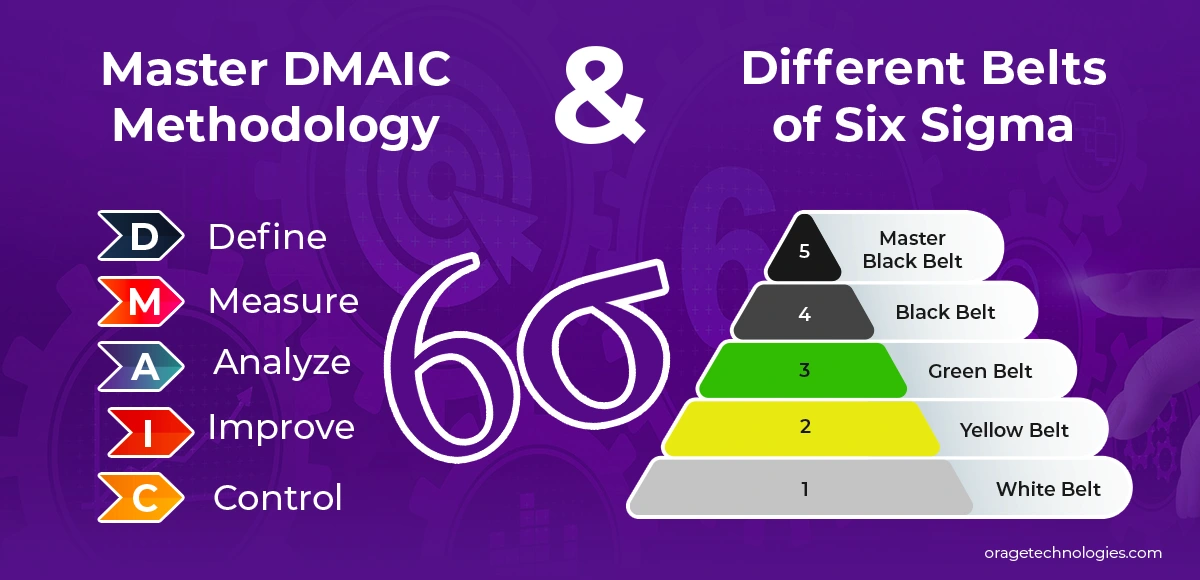

What is DMAIC?

Six Sigma is based on DMAIC Methodology that throws light on the five important players of any improvement project.

DMAIC stands for:

- Define

- Measure

- Analyze

- Improve

- Control

Define Phase

As Charles Kettering once said, “A problem well stated is a problem half solved.” Defining and understanding the problem is the first step toward the success of any business goal. Clarity, focus, and alignment with goals is very important. In this phase, the team should know the following things:

- What the project is about

- Why it matters

- What success looks like

- Who’s involved

- By when the goal should be achieved

The Define phase includes three key steps:

1. Create the Problem and Goal Statements based on SMART

2. Complete the Project Charter like a project roadmap that should include key metric (Y), expected benefits, scope, milestones and signatures.

3. Develop a SIPOC (Suppliers, Inputs, Process, Outputs and Customers) Diagram that will offer a high level overview of the process. SIPOC helps understand what to improve, what inputs will be required and what will be the output. Moreover it also involves the knowledge about suppliers and the target customers.

Measure Phase

Now that we know the problem and the goal, we also need to know “how big is the problem?” what is the frequency etc. This means we need to measure things for smart and strategic decisions. The main purpose of this phase is to define the baseline and quantify the current state.

This phase can be dealt in 5 steps

1. Develop a Data Collection Plan by understanding what data to collect, where you’ll find these data and how much of these data is required.

2. Conduct a process mapping with listing the steps involved, potential bottlenecks, where the inputs come from and where the output will go.

3. Conduct measurement analysis by checking if the measuring tool is accurate, repeatable and reproducible.

4. Measure the Y (Performance Output) by asking “how often does Y meet the requirement?”, “What’s the defect rate or variation?”, “How does performance compare to customer expectations?”

5. Analyze Process Capability by measuring the consistent performance within acceptable limits. In this stage you should measure Upper Specific Limit (USL), Defect Rate, Yield and Sigma Level.

Analyze Phase

The third and the most critical phase is the Analyze Phase because this is the point where you need to question and find the million dollar question: “Why is the problem happening?”.

The Analyze phase ensures that you don’t treat symptoms, you solve root causes (X), and understand the relationship between X and Y in the equation.

Y = f(X).

The Analysis phase includes three key steps:

1. Brainstorm the various potential causes

2. Organize X’s Using a Cause-Effect Diagram or Fishbone or Ishikawa Diagram

3. Shortlist the Likely X’s

4. Create a Data Collection Plan with theory, type of test required, Data needed, Quantity of data, Data source and collection timeline

5. Validate the Key X’s with Hypothesis Testing. It can be done for either discrete data using bar charts and pareto charts or for continuous data using histograms, box plots, dot plots.

Improve Phase

The most action oriented phase is the improve phase where root causes (the proven Xs) are transformed into practical, tested, and impactful solutions that improve the Y (output). The core goal of the Improve phase is to develop, test, and implement solutions that eliminate the root causes of the problem.

Key Steps in the Improve Phase:

- Generate potential solutions through techniques like six thinking hats, anti brainstorming, subject matter expert inputs.

- Evaluate and shortlist the best ones by using tools such as Effort-Impact Matrix, Cost-Benefit Analysis, Pugh Matrix, DOE (Design of Experiments).

- Select the optimal set of solutions to reduce risk by using FMEA (Failure Modes and Effects Analysis) to identify and prioritize potential failures.

- Apply mistake proofing or Poka-Yoke to ensure that errors are prevented—or caught instantly if they occur. There are three levels: prevention, facilitation and detection.

- Implement solutions through pilot testing

- Plan full-scale implementation that covers stakeholders communication, training needs, process documentation, resource allocation and rollout strategy.

Control Phase

The Control phase is the fifth and final phase of DMAIC. And it is responsible for ensuring the improved process continues to perform at the desired level, long after the Six Sigma team has disbanded. It’s about building mechanisms that allow the process to run smoothly, without constant oversight, and avoid backsliding into old habits.

Key Steps in the Control Phase:

1. Develop a control plan is your blueprint to ensure the process stays on track including: What to control, Target values or acceptable ranges, How to measure and monitor performance, When to take action and what action to take, Who is responsible for monitoring and intervention

2. Implement SPC Charts (Statistical Process Control) for random variations that happen, don’t overreact to every little fluctuation.

3. Update Procedures, Train Teams, and Transfer Ownership

4. Validate Financial Impact by considering the improvement goals were met and the financial benefits (e.g., cost savings, reduced waste) are real and measurable

Key Roles of Executives and Champions in Six Sigma Projects

Six Sigma isn’t just a set of tools or a clever methodology, it’s a culture of continuous improvement that runs across the organization. But for this culture to thrive, strong leadership is critical. That’s where executives and project champions come in. Here is the hierarchy of leadership;

- CEO – Chief Executive Officer

- CFO – Chief Financial Officer

- COO – Chief Operating Officer

- CIO – Chief Information Officer

- Vice Presidents

- Directors

These are the decision-makers who steer the ship. Once a company decides to adopt Six Sigma, these leaders are responsible for making it part of the business strategy.

Here’s what Six Sigma executives typically do:

- Align Six Sigma projects with strategic and annual goals

- Create project selection criteria

- Review and approve key projects

- Assign project champions

- Ensure the availability of resources and budget

Executives set the direction, and make sure the entire organization is on board.

Levels of Expertise in Six Sigma

You must have heard of the belt system in martial arts, but do you know Six Sigma, following a process of improvement also has a belt system. This belt system ensures a structured and hierarchical approach to training and development. The various colours represent the level of expertise of belt and each has its own set of training, roles and responsibilities.

White Belt: Introduction to Six Sigma

The White Belt is a beginner’s belt where the learner is introduced to basics of Six Sigma such as

- Basic concepts

- Learning quality thinking and process orientation

- Know the benefits and inculcate awareness about this methodology.

The goal of this foundational level is to spark interest and light up awareness about the six sigma. The people with white belts are endowed with the role to support local efforts and assist small teams.

Yellow Belt: Basic Tools and Team Support

The yellow belt is a first level where the champions are introduced to the DMAIC Methodology. In this level, they:

- Understand mapping

- Voice of Customer

- Delve into the root cause analysis

- Brainstorm problem solving techniques

At this level, individuals learn some of the problem solving tools and skills and then get involved in leading small scale initiatives within departments. They may serve as team members of a larger DMAIC project that is led by Green or Black Belts.

Green Belt: Project Leadership with Data Analysis

Green Belt is the next level of expertise where the individuals are trained to lead DMAIC projects on a part time basis. The training in this level includes:

- Learning and using all five DMAIC phases

- Understand statistical data analysis

- Practical knowledge with real time projects

- Try and test the problem solving framework.

The goal of this level is to prepare individuals to take ownership of process improvement in their functional areas. The champions with green belt of six sigma are responsible to lead medium projects while majorly focusing on their day to day job roles.

Black Belt: Full-Time Project Experts

Black Belts are full-time Six Sigma professionals who take on complex, cross-functional projects. In addition to everything taught at the Green Belt level, Black Belt training includes:

- Advanced statistics

- Process capability analysis

- Hypothesis testing

- Design of Experiments (DOE)

Now the experts are eligible to lead high-impact, strategic projects that drive measurable improvements across departments. The Black belts manage critical projects assigned by senior leadership, mentor Green Belts, and bring technical depth to the Six Sigma program.

Master Black Belt: Strategic Leader and Mentor

Master Black Belts are the highest-level Six Sigma experts. They receive advanced training in:

- Statistical modeling and simulation

- Project and change management

- Coaching and leadership

- Curriculum development and training delivery

They build Six Sigma capability across the organization by mentoring Black Belts, guiding project strategy, and training future practitioners. The Master Black Belts are responsible for maintaining the quality and consistency of Six Sigma programs. They may be internal experts or external consultants.

The Bottom Line

Six sigma and lean six sigma are two of the best methods to inculcate leadership in yourself or any organisation. As it is based on the DMAIC phases, it helps define, measure, analyze, improve and control the problems and risk factors. It works well for every type of industry and organization as it is for improvement and problem solving.

Also Read: Types of Email Marketing: A Complete Guide

Divya Stuti, with over 5 years of experience in Digital Marketing & Content Writing, has a knack for turning complex Marketing strategies, trends, and jargon into interesting and easy to digest blog posts. Whether she’s breaking down the SEO, Social Media or decoding campaigns, Divya knows how to make marketing feel exciting and easy to understand. Armed with a sharp eye for strategy and a storyteller’s instinct, she writes with clarity, creativity, and just the right dose of wit.

More Posts